Scaffolding

Essential Scaffold Components

Table of Contents

A single scaffold bay incorporates a variety of parts, each with their own purpose, to create functioning workspace. All pieces fit together exactly to safeguard workers while also maintain strength and stability for extended periods of time. The list below covers Kwikstage scaffold components, but, many parts below are universal across a variety of different systems.

Regular Scaffold Pieces

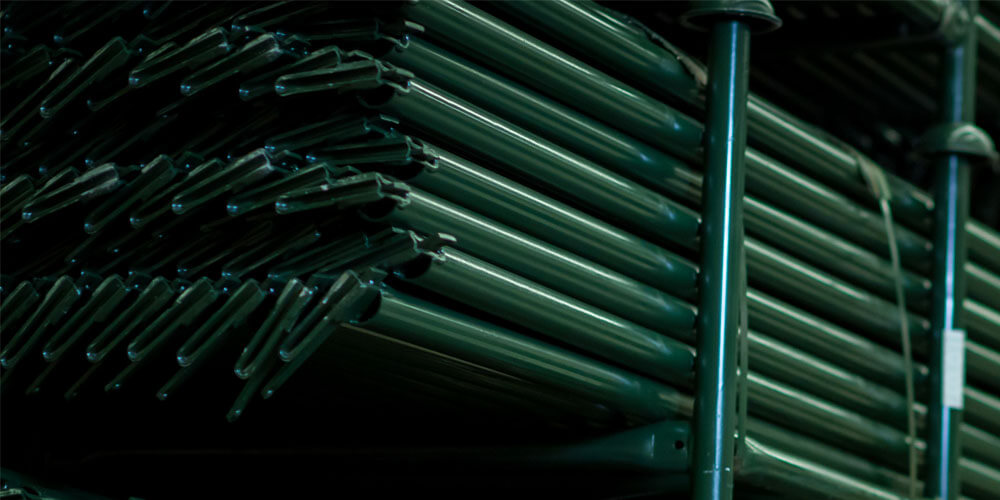

Standards

Standards act as vertical supports on a scaffold system, transferring weight form the top to the bases and flooring below. Each has V-pressings portruding from the tube, allowing Transoms, Ledgers, and a variety of smaller cogs to attach.

Open End variations allow U-Heads to sit at the top, turning Kwikstage structures into a makeshift formwork system.

Ledgers

Although not load-bearing, Ledgers are vital to any Kwikstage system. They space Standards according to industry standard bay lengths and can act as temporary Hand Rail Posts.

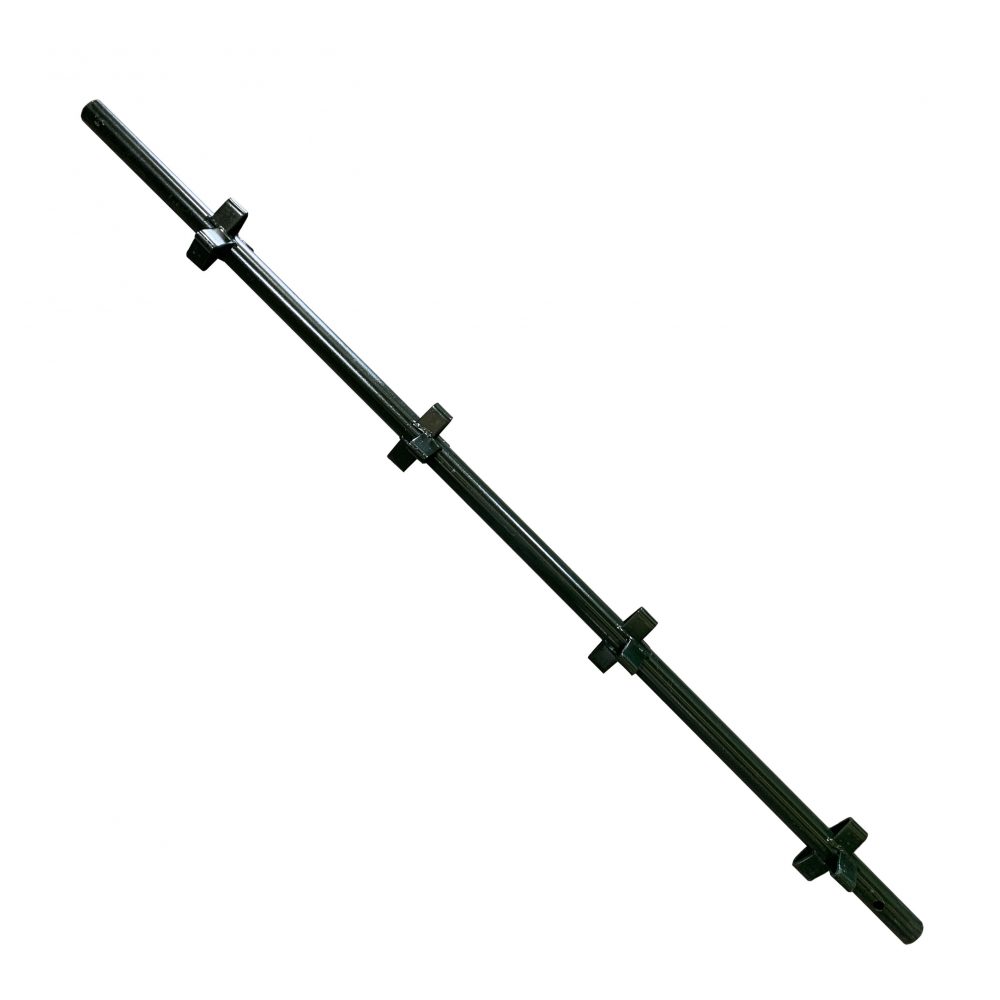

Transoms

Regular Scaffold Transoms space Standards at right angles to Ledgers. A key difference is their load-bearing capacity, acting as supports for planks.

Truss support variants are ideal for systems holding high loads.

Ladder variants support boards similarly, however, their design creates an opening on the platform to place a ladder for access between different bay heights.

Toppers

By placing atop of Kwikstage Standards, scaffolders can create a flat stable surface on top.

Planks

Steel Planks are placed in groups of three, five, seven or more depending on the size of the bay. Held in place by the Transom ‘T seat’, they create a platform for personnel to complete their work. A Frame Planks are similar, however, a hook on each end sits atop individual frames on either side. Both variants utilise galvanised steel.

Timber Boards offer an affordable alternative to steel variants. While employing laminated veneer lumber in manufacturing, steel is often more durable and long-lasting.

Hop Ups

Hop Ups can create wider platforms for builders requiring additional space. They are capable of supporting three extra planks depending on the size used. Two and Three Board Hop Ups can also include spigots to create makeshift handrailing.

Screw Jacks

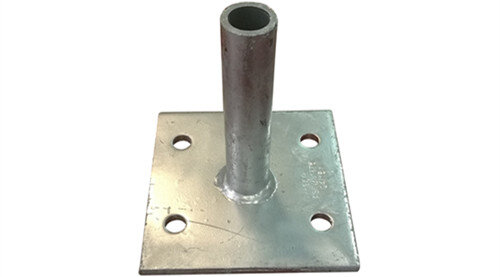

Regular Screw Jacks act as a base, seprarting the scaffold from the ground. The screw enables kwikstage bays to remain level despite and any change in height between the platform and ground.

Swivel Jacks have the same function, but the direction of the bottom plate can move ensuring a level structure is maintained even on sloped surfaces.

Base Plates offer the same load-bearing capabilities but without the benefit of adjusting the height of the Standard or angle of the base.

Sole Boards sit under Screw Jacks as a buffer or for uneven terrain. They distribute weight over a greater surface area so as to prevent any damage forming on solid ground. On worksites with an soft surface, Sole Boards are vital to providing a stable ground on which the scaffold can sit.

Additional Scaffolding Components

Tubing

Aluminium or steel tubes connect with couplers to create load-bearing structures without the rigidity of modular scaffolds. Steel tubes are forbidden by law when within a close vicinity of live power lines.

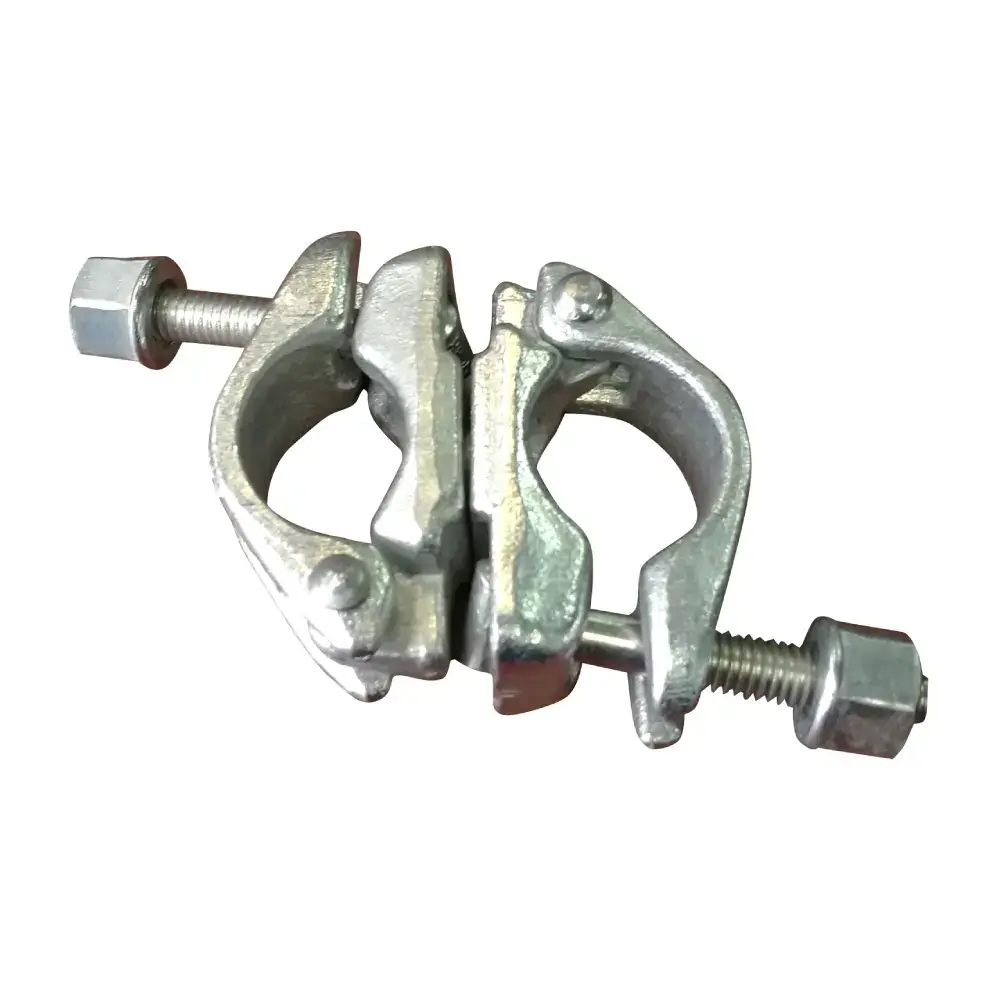

Couplers

A key component for tube and coupler scaffold systems, each coupler seen has a specific function and allows tubing to attach at varying angles while still retaining structural integrity.

Kickboard

Kickboards attach at right angles to the scaffold platforms. Their unique function is to prevent foreign materials falling off the platform and potentially injurying anyone at ground level.